Technical Data

• Enclosure IP67 compliant

• Flexible adaptation, such as the adding of stations and changing of specifications,

is made possible with the use of a multi-pin connector manifold.

• Space-saving design with one side solenoid and fittings all positioned on one side,

allowing free mounting

• No screws and one clamp structure for reduced recombination labor

• A variety of common wiring methods are available.

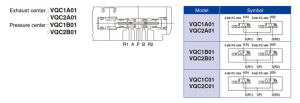

• 4-position, dual 3-port valve

• Manifold type no.: VV5QC11, VV5QC21

Other Data :

> Safety Instructions

> 3/4/5 Port Solenoid Valves/Precautions

> Selection/Technical Data

> Green Procurement (RoHS)

Standard: 0.4W(Reduced by 60% compared to current model)

High-pressure (1 MPa, Metal seal): 0.95W

■Applicable to EX600 (Input/Output) serial transmission system (Fieldbus system)

■The EX260 series supports safety communication (PROFIsafe).

• This is a Fieldbus unit which supports safety standard ISO 13849-compliant safety circuit constructions.

• Using the safety communication protocol

Refer to the EX260 Web Catalog for details on units that support the safety communication protocol.

When using a manifold valve within an ISO 13849-compliant safety system, the device needs to be considered from both the pneumatic circuit and the electric side.

Devices (including valves) need to be selected based on whether their functions are in line with the safety level of the equipment as a whole.

The use of valves that have been validated as being compliant with ISO 13849-2 may be required.

For details on valves that have been validated, please contact SMC.

In addition, refer to “Safety Instructions” for precautions on model selection.

■Connector entry direction can be changed with a single push. (F/P kit)

The connector entry direction can be changed from the top to the side by simply pressing the manual release button.

It is not necessary to use the manual release button when switching from the side to the top.

■A wide variety of prepackaged wiring configurations

・Our six standard wiring packages bring a world of ease to wiring and maintenance work, while the protective enclosures of four of them conform to IP67 standards.

・The S kit is compatible with a combined I/O unit. (Not applicable to Gateway unit)

■Connector type manifold

■Dual 3-port valves, 4 positions

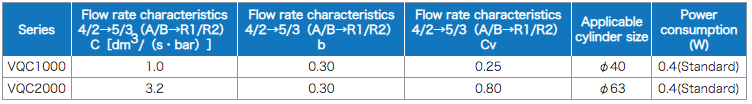

VQC1000/2000 (Rubber seal only)

・Two 3-port valves built into one body

・The 3-port valves on the A and B sides can operate independently.

・When used as 3-port valves, only half the number of stations is required.

・Can also be used as a 4-position, 5-port type valve.